School buildings in developing countries

Practical Action

framework structure within the walls. The elements of the ring beam, bracing or structural

framework would need to be made of a tough and flexible material such as timber or

reinforced concrete with adequate steel reinforcement. Any locally applicable seismic design

and building codes must be strictly adhered to.

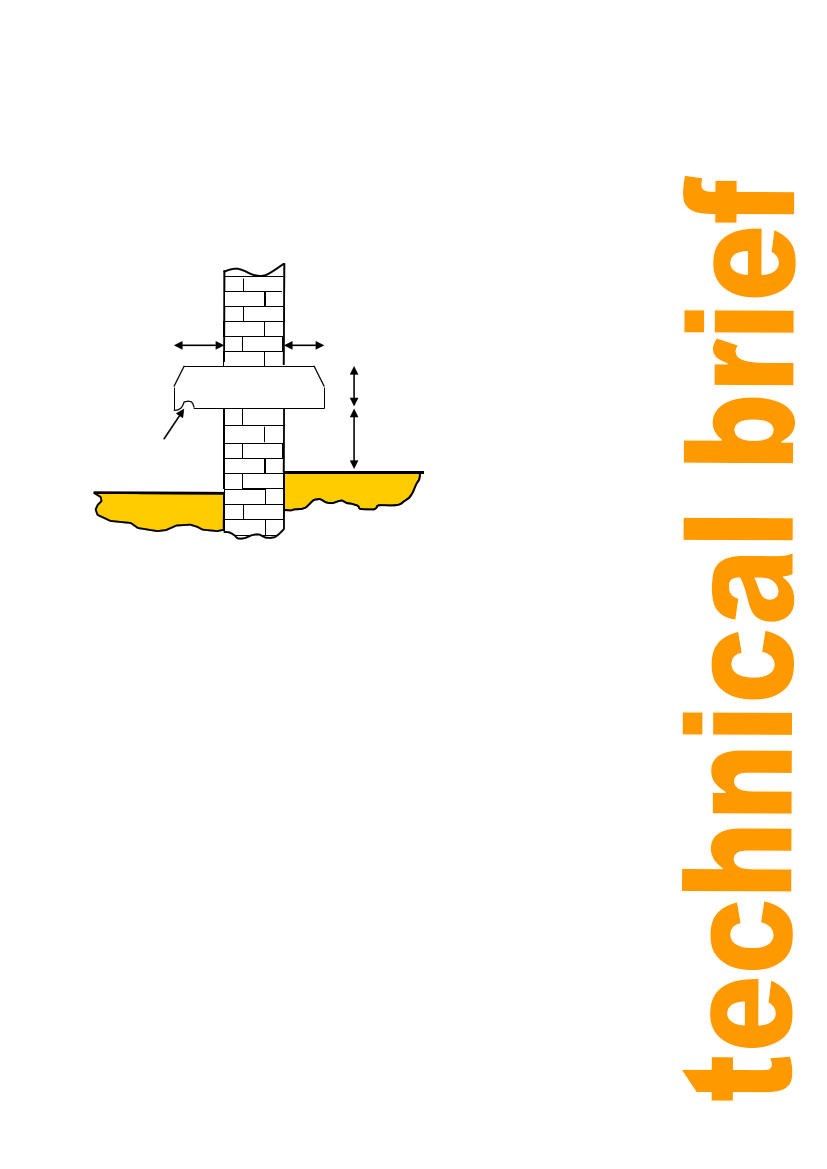

Where there could be a termite problem a termite barrier would need to be inserted near the

bottom of the wall. One possible option is shown below. This is of concrete and would need

to be well-made to ensure that there are no cracks in it which termites can penetrate and

enlarge.

5 cm

5 cm

10 cm

drip 15 cm

Ground Level

Floor level

Figure 5: Termite barrier

An external plaster or render would help to protect the building fabric from weather damage,

improve appearance and fill in any holes which could harbour insects and dirt. As with the

mortar it is important that the plaster is no stronger or harder than the material to which it is

bonded, particularly for relatively weak and friable materials such as earth or soft stone. A

plaster made only with Ordinary Portland Cement as the binder would be too hard for most

materials, and there is the risk that water penetrates behind it causing the plaster to fall off

and sometimes taking pieces of the material to which it is bonded with it. Use of a lime and

cement mixture, lime only, or lime-pozzolana for the binder would almost always be

preferable to just using cement. Typical mix proportions of plaster mixes are one part lime to

two of sand, one part lime to two of pozzolana (such as some types of volcanic ash or finely

ground burnt clay) to nine of sand, or one part cement to two of lime to nine of sand. Plaster

needs to be well-bonded in to the surface to which it is fixed, so a good key needs to be

provided. This can be done by removing some of the mortar from the joints to create grooves

(raking), making grooves in the surface or fixing a wire frame tightly to the wall. Plaster is

applied in two, but preferably three thin layers. The layers or coats would preferably each be

less than one centimetre thick, but certainly so for the final or finishing coat which needs to

be the thinnest.

The first coat is applied, scratched to create a key for the second, then allowed to harden for

several days before the second is applied. Keeping a cement-based coat moist would help it

to harden, while with a lime-based coat allowing the drying to take place only very slowly

would help to reduce cracking. The procedure is repeated for the second coat if a third coat

is to be added. The finishing coat is made with a richer mixture (containing more binder),

and a fine sand so that it can produce a surface of smooth appearance.

Walls can also be plastered or painted internally. A white gypsum or lime-based surface

makes a room seem lighter, can help to improve acoustics and creates a smooth surface

where insects and dirt have difficulty accumulating. Gypsum is a particularly useful

plastering material, but is not recommended for external use, except in dry climates, as it is

12